How Amino Acids are Made

What are amino acids made of?

Amino acids are chemical compounds whose molecules contain a basic amino group (-NH2) and an acidic carboxyl group (-COOH).

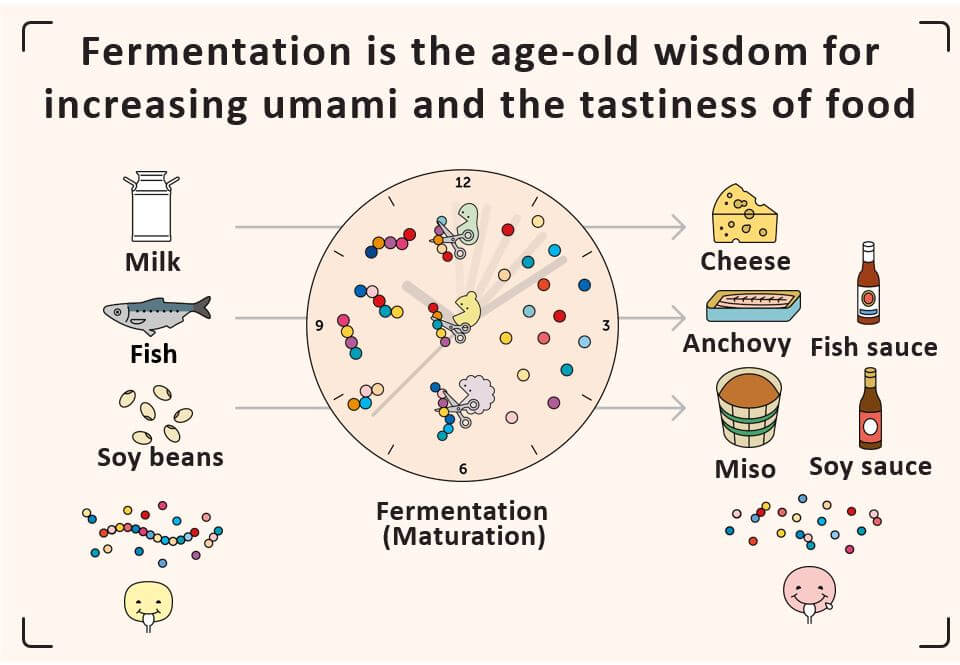

Amino acids are made from plant-derived ingredients. Fermented products such as miso and soy sauce are made by processing soy or wheat with a koji culture. The fermentation process breaks down the protein and turns it into amino acids. Miso and soy sauce are examples of the long-established use of amino acids in Japanese cuisine to make food even more delicious. The amino acids used in food products are mostly made by fermenting plant-derived ingredients in the same way that miso and soy sauce are made.

Fermentation is a natural process

In amino acid fermentation, amino acids are made by fermenting ingredients with a culture medium containing microorganisms such as probiotic bacteria. These microorganisms turn the ingredients into food and other substances that they need. An ingredient such as molasses is also added to are added to help the microorganisms multiply and make amino acids. The Microorganisms contain enzymes that accelerate the reactions involved in breaking down ingredients and synthesizing new substances. The fermentation process is a series of reactions involving between 10 and 30 different enzymes.

Other ways to make amino acids

In addition to fermentation, there are other ways to make amino acids, such as enzymatic reaction, extraction and synthesis.

In the enzymatic reaction process, one or two enzymes are used to turn an amino acid precursor into the right amino acid. In this method there is no need to multiply microorganisms by converting the specific amino acid, and there is no long process starting from glucose. The enzymatic reaction process is ideal if the precursor substance has a low cost.

Amino acids can be produced by breaking down proteins. This is known as the extraction method. However, the quantity of amino acids in the source protein limits the quantity of amino acids that can be produced, so this method is unsuitable for making mass quantities of specific amino acids.

The synthesis method uses chemical reactions to make amino acids, and was widely used in the early development of amino acids production techniques. The problem with this method is that chemical reactions make equal amounts of L- and D-amino acids, so a the D-amino acids must then be converted into L-amino acids. Requiring extra processing steps and equipment, this method was more expensive, and was therefore gradually phased out. However, it is still used to make glycine, which does not occur in D- and L- forms, and for amino acids that are equally useful in either D- or L- forms.

The advantage of the fermentation method is that it enables the production of mass quantities of amino acids at a low cost with relatively small facilities. This method helped grow the amino acid market. In the 1960s, manufacturing of glutamate shifted from extraction to fermentation and the manufacturing of other amino acids followed suit.

Learn more about the Ajinomoto Group

Get to know us

- What is lactose fermentation? Microorganisms can preserve foods

You may also like

Unlocking amino acids’ potential: passion and a bit of luck

This article explains the links between nutrition and amino acids and explains how amino acids can solve the world’s health and nutrition challenges.