Controlling insulation

with microfilm—

Ajinomoto Build-up Film

interlayer insulation

Ajinomoto Build-up Film (ABF)

< Table of Contents >

-

The standard for high-performance CPUs -

Insulation material shifts from liquid to film based on amino acid technology -

Integration of organics and inorganics in a microfilm -

Precision circuitry, through nanoscale to milliscale build-up -

Processing and optimization expertise -

An essential component of the emerging mobile, automotive, home, and social infrastructure

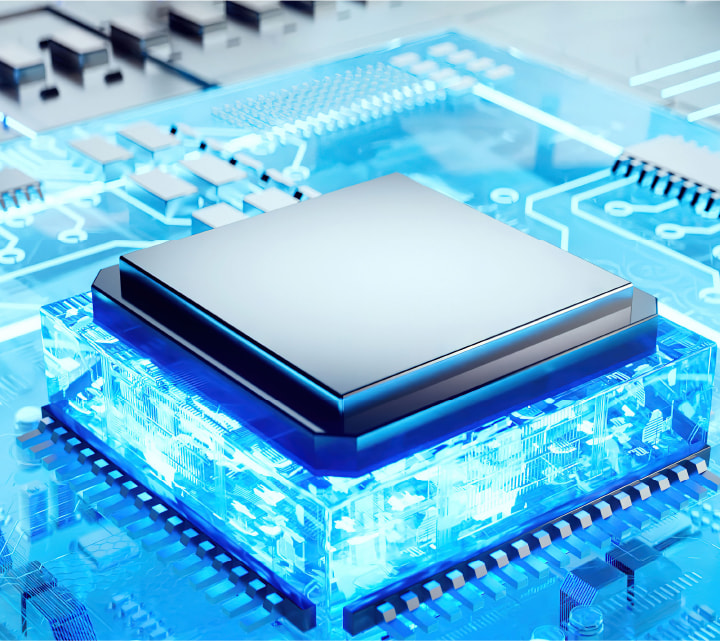

The standard for

high-performance CPUs

It is not commonly known that the Ajinomoto Group provides a benchmark component of computers. In fact, Ajinomoto Build-up Film (ABF) can be found at the heart of most of the world’s personal computers, where it provides electrical insulation of complex circuit substrates for high-performance central processing units (CPUs).

The story of ABF begins in the 1970s, sees its initial adoption in personal computers in the late 1990s, and continues to evolve to this day in concert with advances in CPU performance.

The need for advanced CPU substrates grew rapidly in the 1990s with the transition from MS-DOS to Windows operating systems, the rise of large-scale integration in CPUs for personal computers, and the increase in terminals from about 40 in early CPUs to a thousand or more today. This led to a shift from “lead frame” configurations to CPUs mounted on multilayer circuit substrates containing complex wiring patterns, creating an urgent demand for new insulating materials.

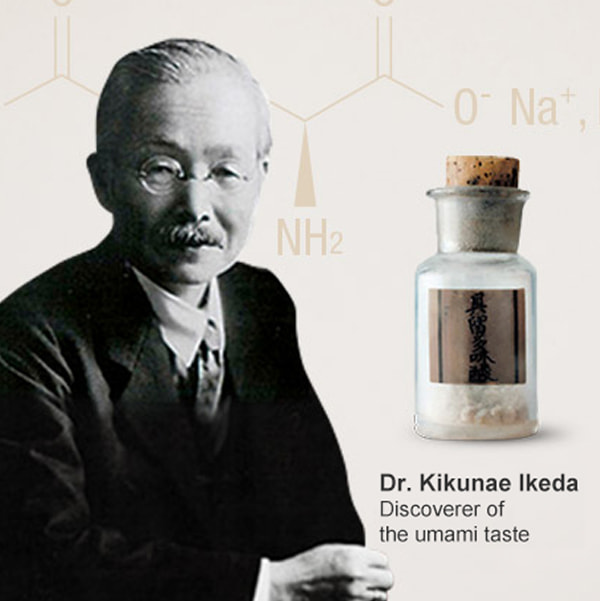

Insulation material shifts from liquid to film based on

amino acid technology

The Ajinomoto Group began basic research on applications of amino acid chemistry to epoxy resins and their composites in the 1970s. This ultimately led to the development of advanced insulators for CPU substrates. As a late entrant to this field, the Ajinomoto Group’s focus on film differentiated our product from conventional ink-type insulators and resulted in a material that resolved significant problems posed by the use of conventional insulators in high-performance CPUs. When ABF became available to manufacturers, it met a fast-growing global demand.

Integration of organics

and inorganics in a

microfilm

The basic objective of the R&D that led to ABF was to find a resin composition that would determine the performance of the insulation material, provide the requisite functions of an electrical material, and facilitate film formation. The Ajinomoto Group’s expertise in fine chemistry was applied to developing a formulation that combined organic epoxy resins, hardener, and inorganic, microparticle filler. Major challenges included developing a methodology for homogeneous mixing of organic and inorganic substances that inherently resist uniform dispersion, and providing superior insulating properties and superior processing characteristics. To meet these challenges, the R&D team created a thermosetting film with high durability, low thermal expansion, ease of processing, and other important characteristics. Named ABF, the film was first adopted by a major semiconductor manufacturer in 1999. Since then, it has become a product of choice for nearly all high-performance CPUs, supported by R&D that has continuously evolved to meet the needs brought on by rapid advances in circuit integration.

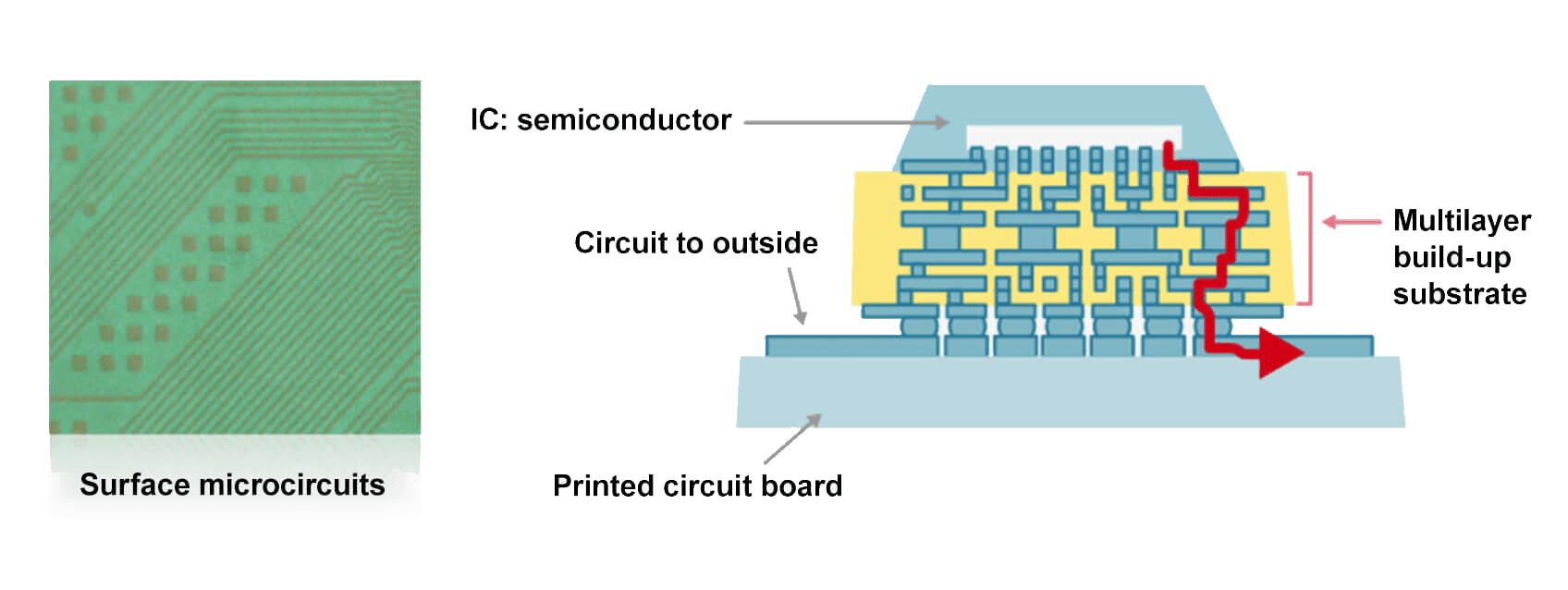

Precision circuitry, through nanoscale to milliscale build-up

Advances in circuit integration have made possible CPUs composed of nanometer-scale electronic circuits. These circuits must be connected to the millimeter-scale electronic components in electronic equipment and systems. This can be accomplished by employing a CPU “bed” composed of multiple layers of microcircuits, known as a “build-up substrate.” ABF facilitates the formation of these micrometer-scale circuits, because its surface is receptive to laser processing and direct copper plating. Today, ABF is an essential material for forming the circuitry that guides the flow of electrons from nanoscale CPU terminals to the millimeter-scale terminals on printed substrates.

Processing and optimization expertise

The quality of ABF is constantly improving in line with rapid upgrades in CPU performance. This requires ceaseless R&D into insulating resins with differing properties, refinement of product characteristics, processing technologies to meet emerging customer requirements, and repeated testing and verification.

Achieving the thermal stability demanded by the heat-generating CPU environment, optimizing plating processes essential for circuit formation, and facilitating laser processing are just a few of the many challenges that call for specialized knowledge and expertise. As CPUs evolve and diversify, these skills are essential to producing the optimum ABF-based circuit substrates that meet customer requirements.

An essential component of the emerging mobile,

automotive, home, and

social infrastructure

Semiconductors are the foundation of today’s information and communications technology (ICT) infrastructure. Further semiconductor downsizing and higher-level multifunctional performance will soon enable smarter cell phones and related devices, as well as functions for control, safety, and communication of a multitude of devices in automobiles and homes. The Ajinomoto Group will continue advancing its ABF technology and its specialization to help drive the further downsizing, higher performance, and spread of semiconductors. ABF is already essential in many sectors, and its evolution will contribute to the betterment of society.

Find out more:

The Ajinomoto fine-techno is a company which bears the core of the fine-chemicals enterprise of the Ajinomoto Groups including insulating material “Ajinomoto Build-up Film”(ABF).

Document includes:

・Overview of Ajinomoto Fine-Techno Co., Inc.

・Development of Ajinomoto Build-up Film® (ABF)

・Electronic Materials Business Update

Behind-the-scenes story of Ajinomoto Build-up Film

Another Innovation Story