Putting life’s

essential proteins to

work to deliver

sustainable global food solutions

Enzyme technologies

< Table of Contents >

What are enzymes?

Enzymes are proteins essential for maintaining life. Present in all living things, including microorganisms, enzymes are catalysts, meaning they speed up various types of reactions. In the body, for example, enzymes involved in digestion metabolize food, providing energy for vital biological processes.

In the human body alone, there are over 3,000 types of enzymes that are found everywhere from saliva to the stomach and liver. Some work to break down alcohol, others to maintain skin cells.

Each type of enzyme has a unique shape that determines what kind of substance, or substrate, it can react with. For a reaction to take place, the substrate molecules must precisely match the shape of the enzyme’s active site—the way a key fits a lock. Due to their specialized nature, most enzymes can catalyze just one type of reaction. Degradative enzymes are ones that split apart molecules of fat, protein, or carbohydrates like sugar and starch. Other types of enzymes bind substrate molecules together. Because enzymes are left unchanged by these reactions, they can be used again and again, provided optimal temperature and pH conditions are maintained. Absent these optimal conditions, enzymes become less reactive, or denatured.

Koji mold (Aspergillus oryzae) growing on rice grains

Since ancient times, humans have harnessed the power of enzymes like those found in microorganisms such as mold to assist with food production. Enzymes are essential for fermentation, for example, which preserves foods and makes them more nutritious and delicious. Through fermentation, raw ingredients like milk, grain, and fruit are converted into cheese, yogurt, and a variety of alcoholic beverages. Enzymes speed up fermentation by liquefying and saccharifying starch, namely breaking it down into sugars. In Japan, enzymes found in koji mold—which forms naturally on rice and other grains—have been utilized for centuries to make soy sauce, miso, sake, and other fermented foods out of rice, barley, and soybeans. With enzymes, limited food resources can be stretched farther, yielding a diverse array of final products.

Over time, as fermentation technology has advanced, the functions of enzymes have also come to be better understood. Until recently, degradative enzymes comprised the majority of enzymes used by the food industry, such as in meat processing, where protein-degrading enzymes have long been used to tenderize steaks and hamburgers. But newer research has opened up a range of applications that take advantage of the ability of certain enzymes to bind molecules together and promote elasticity and firmness in some foods. It was for this reason that the Ajinomoto Group turned its attention to transglutaminase.

Learn more about how fermentation preserves and improves foods

What is transglutaminase?

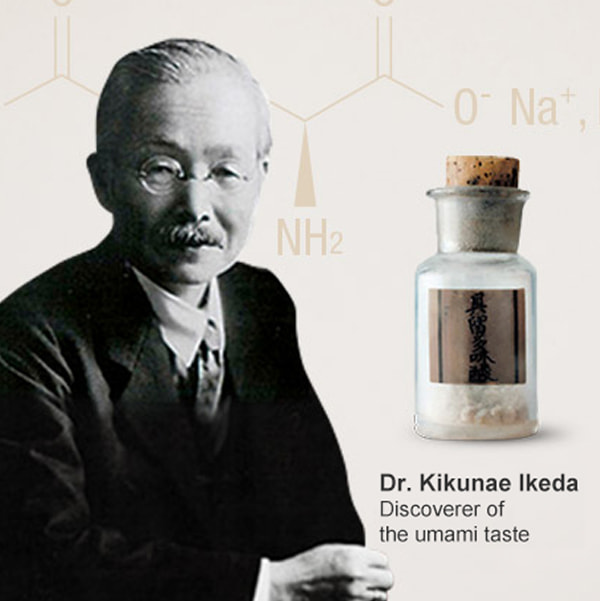

Transglutaminase is an enzyme that binds proteins in the body into polymers, making it indispensible for creating barriers and stable structures such as skin. Unlike other enzymes that have been known for centuries, it was first described and named only in the late 1950s.

In 1980, one of Ajinomoto’s R&D teams began working on an early form of plant-based meat made from soy protein. One challenge to developing meat from soy protein had always been the difficulty of recreating the texture of animal protein. While searching for a substance capable of imparting the required elasticity and firmness to soy protein, Ajinomoto Group researchers discovered an enzyme called transglutaminase. This led to revealing the potentiality of this enzyme to form covalent bonds between residue side chains of the amino acids glutamine and lysine. This reaction allows proteins to coagulate into larger proteins and makes it possible to create soy protein characterized by strong, elastic protein fibers similar to those of animal protein.

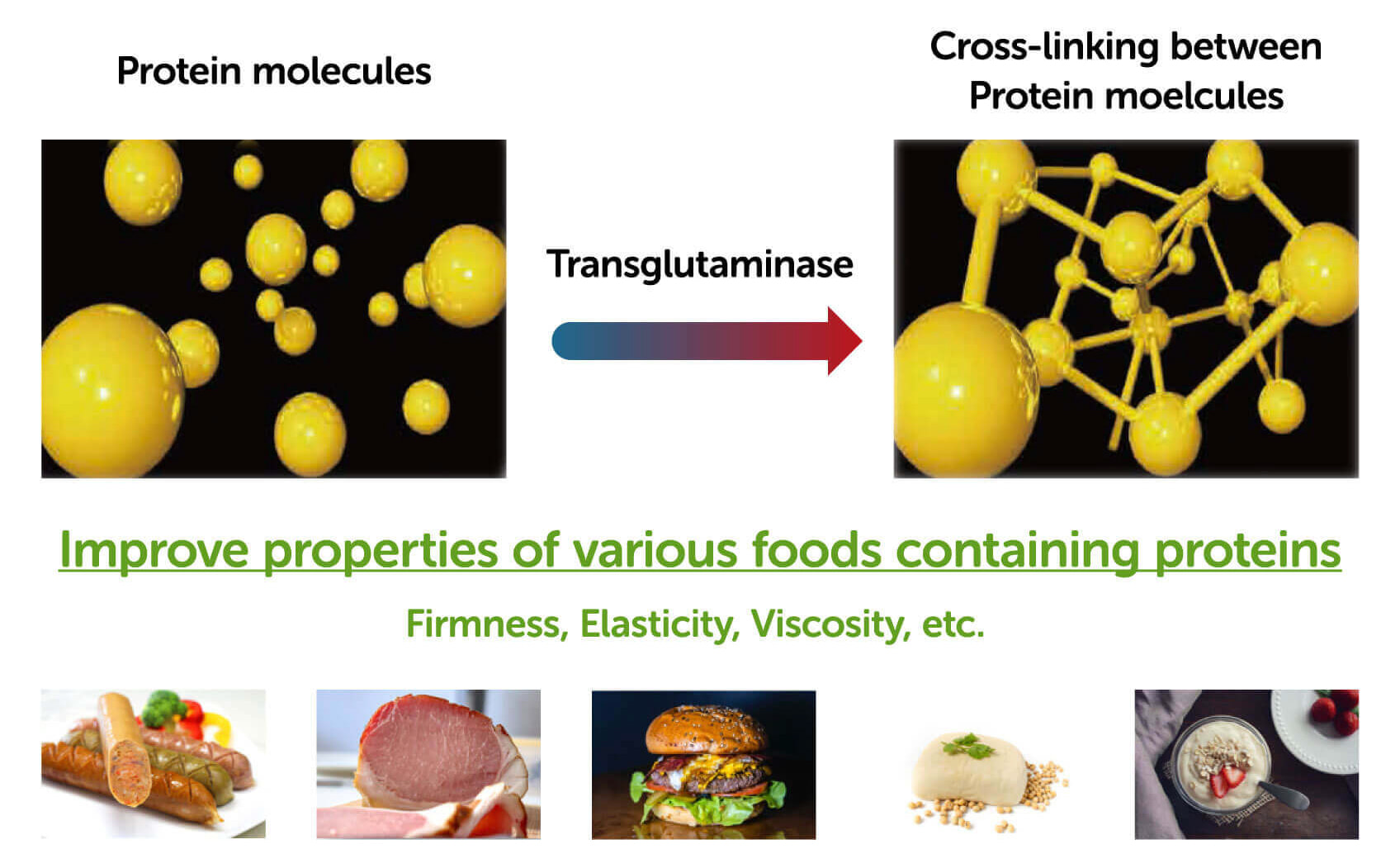

Because transglutaminase reacts with a wide variety of proteins, it is useful in a broad range of food applications. Sodium caseinate solution, for example—a protein found in milk that is resistant to gelling even when heated—can be caused to gel at room temperature when treated with transglutaminase. This has had important implications for yogurt and cheese production. Moreover, since transglutaminase is active at temperatures above 0°C and has a wide optimal pH range of 5.0 to 8.0, it can be utilized in food applications ranging from sausages and meat patties to noodles, tofu, and prepared foods.

ACTIVA®—the world's first transglutaminase

preparation for food applications

ACTIVA®—the world's first transglutaminase preparation for food applications

The Ajinomoto Group has been expanding its food enzyme solutions by combining not only transglutaminase but also other enzymes with various food materials. While ordinary degradative enzymes typically destroy the natural texture of meat by breaking down proteins, the Group has developed proprietary enzyme treatments that tenderize meat without sacrificing its natural texture, yielding high quality products with physical properties such as mouthfeel that food producers and consumers demand. Other products work to break up starch chains in rice to increase water retention without loss of texture, both improving production yields and extending shelf life by preventing retrogradation of starch during storage.

These advanced enzyme technologies are contributing to better food productivity, cost reduction, and more efficient use of food resources. In particular, the Ajinomoto Group has been a pioneer in bonding formulations that are revolutionizing the way shaped meat is produced for applications like grilling and barbecuing. Typically, slicing large cuts of meat generates significant quantities of trimmings that end up being wasted. But using enzyme treatments to bond meat cuts together in a mold before processing yields more uniform slices of meat, decreasing food loss and boosting production efficiency. Food enzymes are now also used in less common applications, such as seafood products like fish balls, and opening up a range of further possibilities.

But the power of enzymes does not end there. Along with societal changes such as an aging population, Ajinomoto’s food enzyme solutions are evolving and finding new food applications like easy-to-eat boneless fish fillets, which are in high demand at hospitals. Enzyme preparations are also being used to develop more health-conscious foods, as they can compensate for the loss of texture that commonly results when salt or phosphates are reduced in meat and fish.

In conjunction with taste and flavor applications that utilize the Ajinomoto Group’s proprietary umami and kokumi applications, the Group’s enzyme technologies have an important role to play in offering comprehensive food solutions that promote global health and nutrition without compromising taste. In addition, they are increasingly being used as clean label materials in plant-based protein products and attracting attention for their ability to contribute to sustainability.

Delivering health and nutrition without compromise

through total, sustainable solutions

The Ajinomoto Group has been expanding its food enzyme solutions by combining not only transglutaminase but also other enzymes with various food materials. While ordinary degradative enzymes typically destroy the natural texture of meat by breaking down proteins, the Group has developed proprietary enzyme treatments that tenderize meat without sacrificing its natural texture, yielding high quality products with physical properties such as mouthfeel that food producers and consumers demand. Other products work to break up starch chains in rice to increase water retention without loss of texture, both improving production yields and extending shelf life by preventing retrogradation of starch during storage.

These advanced enzyme technologies are contributing to better food productivity, cost reduction, and more efficient use of food resources. In particular, the Ajinomoto Group has been a pioneer in bonding formulations that are revolutionizing the way shaped meat is produced for applications like grilling and barbecuing. Typically, slicing large cuts of meat generates significant quantities of trimmings that end up being wasted. But using enzyme treatments to bond meat cuts together in a mold before processing yields more uniform slices of meat, decreasing food loss and boosting production efficiency. Food enzymes are now also used in less common applications, such as seafood products like fish balls, and opening up a range of further possibilities.

But the power of enzymes does not end there. Along with societal changes such as an aging population, Ajinomoto’s food enzyme solutions are evolving and finding new food applications like easy-to-eat boneless fish fillets, which are in high demand at hospitals. Enzyme preparations are also being used to develop more health-conscious foods, as they can compensate for the loss of texture that commonly results when salt or phosphates are reduced in meat and fish.

In conjunction with taste and flavor applications that utilize the Ajinomoto Group’s proprietary umami and kokumi applications, the Group’s enzyme technologies have an important role to play in offering comprehensive food solutions that promote global health and nutrition without compromising taste. In addition, they are increasingly being used as clean label materials in plant-based protein products and attracting attention for their ability to contribute to sustainability.

Another Innovation Story