The Ajinomoto Group Plastic Waste Reduction Initiatives

Towards Zero Plastic Waste

The Ajinomoto Group leverages the superior properties of plastics while addressing environmental issues through measures such as reducing usage, switching to recyclable materials, and establishing systems for collection, sorting, and recycling.

Table of Contents

Three Negative Environmental Impacts of Plastic

1. Global Warming

The manufacturing process of plastics and their incineration as waste emit large amounts of greenhouse gases, raising concerns about their impact on climate change.

2. Resource Depletion

The fossil fuels used as raw materials for plastics are limited resources. As production increases, the risk of resource depletion also rises.

3. Marine Pollution

Plastic waste that leaks into the natural environment can take hundreds of years to decompose. This not only poses a risk of ingestion by wildlife but also leads to the formation of microplastics that enter the food chain negatively impacting ecosystems.

Reducing usage and collecting and recycling plastics are part of the solution.

The Ajinomoto Group set a goal to reduce plastic waste to zero by 2030. This means that we intend to eliminate all plastics released to the environment that are not used effectively.

The Ajinomoto Group's Initiatives

For a Circular Economy Worldwide

The Ajinomoto Group’s Recycling Initiatives: For a Circular Economy Worldwide

Social Initiatives

Switching to Paper Packaging

Participating Organizations

The Ajinomoto Group contributes to the realization of a circular society by participating in organizations that lead environmental initiatives.

FAQ

-

With the increase in plastic production, the amount of plastic waste has also risen. As of 2020, it is estimated that 6.3 billion tons of plastic have been discarded as waste. If this trend continues, it is predicted that by 2050, 25 billion tons of plastic waste will be generated, and more than 12 billion tons of plastic will be landfilled or dumped into the environment.

Source: Ministry of the Environment, Japan

https://www.env.go.jp/policy/hakusyo/r02/html/hj20010103.html -

Packaging plays a crucial role in protecting food and maintaining the quality and safety of products. Plastic is an ideal packaging material because it is inexpensive, lightweight, easily moldable, and can enhance product preservation, quality, and safety.

The Ajinomoto Group leverages these characteristics of plastic in our packaging to ensure the quality and safety of our products while using the minimal necessary amount of plastic. Additionally, we design our plastic packaging to be easily recyclable and aim to support the collection and recycling of plastic after use.

-

In Europe, the European Commission announced the Plastic Strategy in January 2018. This strategy aims to make all plastic packaging reusable or recyclable in a cost-effective manner by 2030, promote the use of recycled materials by companies, and reduce single-use plastics. Additionally, in March 2019, the European Parliament approved a regulation to ban single-use plastic products such as cutlery by 2021.

In Asia, in July 2017, the Chinese government announced the Implementation Plan for Reforming the Management of Solid Waste Imports. This plan indicated that by the end of 2017, the import of plastic waste from households would be banned, and by the end of 2019, the import of solid waste that can be replaced by domestic resources would be gradually stopped. As a result, the export volume to Southeast Asian countries such as Thailand, Vietnam, and Malaysia increased significantly in a short period, leading some of these countries to restrict plastic waste imports due to the accumulation of plastic waste within their territories.

At the United Nations Environment Assembly held from February to March 2022, a resolution was adopted to establish an intergovernmental negotiating committee to develop an internationally legally binding treaty on plastic pollution in the marine environment.

In April 2023, Japan, as the chair country, hosted the G7 Sapporo Climate, Energy, and Environment Ministers’ Meeting. During this meeting, the G7 committed to ending plastic pollution and set an ambitious goal to achieve zero additional plastic pollution by 2040.

Source: Ministry of the Environment, Japan

https://www.env.go.jp/policy/hakusyo/r02/html/hj20010103.html -

It is important to reduce the use of disposable plastic products, choose recyclable products, and use reusable items. Additionally, by being aware that waste can become a resource through sorting, it is beneficial to follow local sorting rules and properly clean and sort waste. Participating in local clean-up activities and adopting an environmentally responsible lifestyle are also effective measures.

-

Regarding the impact on wildlife, plastic has been found in the stomachs of dead seabirds and fish worldwide. Additionally, discarded fishing gear such as nets and traps can harm marine life. It has even been estimated that by 2050, the weight of plastic waste in the oceans will exceed the weight of fish.

While the specific environmental impact is not yet clear, it seems that microplastics, which can contain harmful substances, may enter the food chain and potentially affect ecosystems.

Source: Ministry of the Environment, Japan

https://www.env.go.jp/policy/hakusyo/r02/html/hj20010103.html -

According to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, the average global temperature has risen by 1.09 degrees Celsius from the pre-industrial era to the present. This rate of increase is unprecedented in human history.

Source: Ministry of Education, Culture, Sports, Science and Technology, Japan Meteorological Agency

https://www.mext.go.jp/content/20230531-mxt_kankyou-100000543_9.pdf

-

The Ajinomoto Group uses approximately 68,000 tons of plastic annually in its packaging (as of fiscal 2024).

-

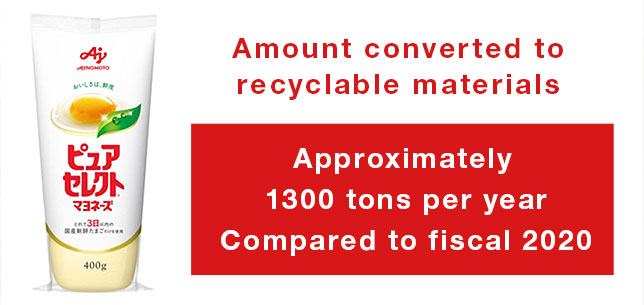

We employ various measures such as compacting packaging materials and trays, reducing the thickness of containers while maintaining their strength, reducing secondary packaging that wraps and bundles pre-packaged items, and switching to paper packaging materials. As a result, in the fiscal year 2024, we reduced plastic usage by approximately 600 tons per year.

-

Addressing the plastic waste problem requires collaboration among industry, government, and the public. The Ajinomoto Group is strengthening cross-industry cooperation within Japan by participating as a founding member of the Clean Ocean Material Alliance platform, which aims to promote innovation. Additionally, we are working to engage with various platforms in other countries and regions to contribute to the creation of plastic recycling systems. For example, in Indonesia, we are collaborating with the city of Surabaya and startup companies to tackle plastic collection.

-

We are collaborating with packaging manufacturers to develop recyclable plastic packaging that can maintain product quality and safety. Additionally, we are exploring the use of non-plastic packaging materials and various means of preserving product quality more effectively.

-

The raw material for plastic is fossil fuel, a limited resource. On the other hand, the raw material for paper is wood, a renewable resource managed through forestry. Wood absorbs carbon dioxide during its growth process, helping reduce one of the causes of global warming.

Additionally, paper is easier to recycle compared to many other packaging materials, and the energy required for its production and recycling is often relatively low. When paper enters the natural environment, unlike plastic that causes environmental issues such as marine pollution, it decomposes relatively quickly. Therefore, generally speaking, paper packaging is considered environmentally responsible.

Of course, the use of paper can also have a significant environmental impact. We’re considering environmental impacts throughout the entire product life cycle when exploring packaging replacements.

-

Compared to plastic, paper has the following weaknesses:

It is vulnerable to applied force, making it prone to tearing and puncturing.

It wrinkles easily.

It is difficult to tear straight by hand when opening.

It is not well-suited to existing equipment designed for plastic.Overcoming these vulnerabilities to achieve the same quality as plastic has been particularly challenging. We collaborated with packaging suppliers and packaging factories to design packaging materials implementing various innovations from multiple perspectives.

-

Typical film packaging is composed of multiple materials (multimaterial), each with its own role. Replacing this with packaging made from a single material (monomaterial) makes it easier to recycle because there is no need to separate the various materials.

However, some barrier materials that do not hinder recycling are used in combination with monomaterials. Developing monomaterial packaging with barrier properties requires innovation, but efforts are being made to achieve more ideal recycling.

-

The Ajinomoto Group favors monomaterials or paper as recyclable packaging materials. The choice among such options depends on the characteristics of the product and the properties of the packaging materials required.

When developing monomaterial packaging using plastic, we first look for materials that ensure sufficient strength and gas barrier properties (resistance to oxygen and water vapor) to maintain the protective function of the packaging. Next, we evaluate whether the packaging is easy to open and use, and whether it can be stably produced in packaging factories. These features are confirmed through actual manufacturing tests.

Typical film packaging is composed of multimaterials (composite materials) with each material having its own role, making it difficult to recycle. Achieving the same performance with monomaterials can be very challenging and requires creativity and innovation.

-

Whether we make plastic a villain or a resource is up to us. There can be no doubt that the leakage of plastic waste into the environment, the acceleration of climate change due to plastic incineration, and the loss of biodiversity are critical plastic-related issues that directly threaten the sustainability of our business. However, for the Ajinomoto Group, plastic is also a necessary material for ensuring product safety and quality, and ultimately for reducing food waste. If we prevent plastic from leaking into the environment and recycle it properly, it can continue to be effectively utilized as a resource.

The Ajinomoto Group aims to balance economic activities and environmental conservation by building resource circulation systems that include reducing plastic usage, switching to recyclable materials, and implementing recycling systems.