Reading Time: 4minutes

Table of Contents

From Kyoto to Paris and beyond, the world is implementing protocols and new practices to move toward greater sustainability. Increasingly consumers expect brands to do their part in helping fight climate change and other environmental problems.

In 2018, the Ajinomoto Group introduced an organization-wide initiative to achieve zero plastic waste by 2030, in part by increasing the ratio of paper in packaging materials. Following on the success of the introduction of paper-plastic composite packaging for umami seasoning AJI-NO-MOTO® and Umami Dashi Hi-Me® in 2022, which resulted in a reduction of 12 tons of plastic per year, the Group next focused its attention on the popular dashi stock product HONDASHI®.

While reduction of plastic waste and improved sustainability were the main driver, the HONDASHI®︎ team were also determined to add value that customers could experience directly. They landed on the idea of taking advantage of the new paper content for coloring, just like we always did as kids. Thought to stimulate creativity, coloring seemed like a pastime kids and their parents could enjoy together during meal preparation time.

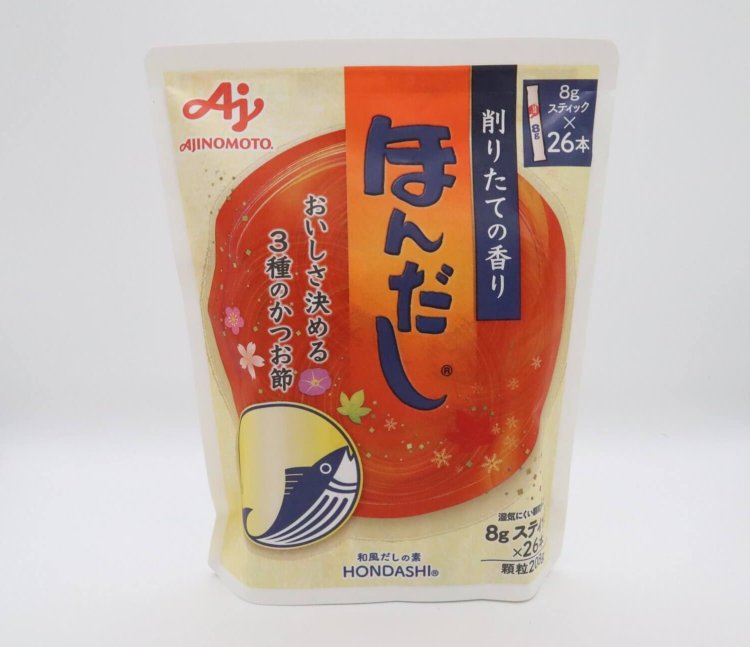

New HONDASHI® package

More than sustainable

Since 2017, HONDASHI®︎ has already featured paper-based sachets and thinner sticks of the concentrated, dried broth. In 2021, development began on introducing paper for the external packaging. As the physical characteristics of each product are different, each new paper introduction project poses different challenges and requires new innovation.

One of the key user benefits of the new HONDASHI®︎ paper packaging is that the package can stand up on its own even when there are only a few sticks left inside, making it easier to store. The other form of added value is family fun: a little coloring book-style design on the back of the package that takes advantage of the physical quality of paper, allowing parents and children to share the fun of drawing.

A team effort

Three people integral in the initiative—Ayaka Mori of the Flavor Seasoning Group, Yusuke Honda of the Packaging Group, and Yu Iijima of the Creative Development Group—speak of the unique challenges they faced. The team defined the key tasks in their mission as determining the right kind of paper packaging, dimensions, and other specifications; verifying that the packaging assembly line was aligned with new specifications; test transporting the product; and then reevaluating the package design based on these investigations before finally releasing the product. Success depended on close collaboration among business units, researchers, materials suppliers, and equipment manufacturer.

(From left) Yu Iijima of the Creative Development Group, Ayaka Mori of the Flavor Seasoning Group, and Yusuke Honda of the Packaging Group

At first the paper was too thick to fit into the outer box, and when they tried making the paper thinner, it tore easily during packaging or transportation. Also, this was the Group’s first attempt to implement paper packaging materials using a filling mechanism where sticks are dropped, and it was very challenging to determine the precise shape and materials required so that the impact of falling sticks would not tear the paper. The team considered various kinds of perforations and shapes to make the package easier to open, and rounded the corners to prevent paper cuts. Honda reports “We tried some 30 different materials and dimensions, and ran four separate factory tests before coming up with the solution.”

Another major challenge was holding down costs. Accommodating paper tended to push up the cost of the materials and also required redesign of the manufacturing facilities. A slight reduction in overall package size helped mitigate costs and further reduce waste.

Still, the biggest issue was delivering new value, and the coloring project was a key feature: a fun design on the back of the package that customers and their kids could enjoy. Iijima notes that “We felt it was important to retain brand consistency by keeping the front of the package unchanged, so we made space for the coloring design on the back.” The paper packaging material supplier managed to fulfill the request to process and print six different patterns, each with a unique drawing. Ajinomoto Group employees with children were interviewed to find out how to optimize the fun paper makes possible. Some of the key insights were that if the pictures were too small, little kids wouldn’t be able to color, and that featuring popular characters could make the design more attractive, and that food pictured in the drawing should be foods kids like.

Mori tells us “I ran to the convenience store late one night to get some colored pencils and try coloring on the package. It became clear that the texture of the package had to be just right.”

The results of this latest initiative are clear: by converting HONDASHI® to paper packaging, the Group reduced plastic waste approximately 32 tons per year. Adding to the achievements with AJI-NO-MOTO® and Umami Dashi Hi-Me®, the success with HONDASHI® takes total annual reduction to 44 tons per year.

Less waste and more fun worldwide

Although the new HONDASHI® package has have only just started to appear on store shelves in Japan, customer comments have been very encouraging: One customer said the paper gives a sense of warmth and refinement, while another found the packaging is cute and soothing. A campaign to invite customers to submit new coloring designs is planned to enhance engagement and find new ways to share new value with customers.

The development team came up with 6 different coloring designs, taking advantage of the qualities of paper to provide some family fun.

The goals of eliminating plastic waste and reducing environmental impact by 50% by 2030 are among the toughest and most important challenges faced by the Ajinomoto Group today. The lessons learned in this project may be applied in introducing paper packaging of other products in Japan and around the world. Outside of Japan, the Ajinomoto Group has introduced paper packaging for AJI-NO-MOTO®︎ in Indonesia and the Philippines. The journey toward more environmentally friendly packaging for Ajinomoto Group seasonings and other food products worldwide is well underway.

Stories you may like

Sustainability Promoter Yukiko Ishikawa on our journey to making the CDP’s Climate Change Company A List for four consecutive years

- Environment

- Food & Wellness

- Sustainability / SDGs

AJI-NO-MOTO® paper packaging: reducing plastic waste

- Environment

- Food & Wellness

- Sustainability / SDGs

The road to zero plastic waste: Ajinomoto Indonesia succeeds through private-public partnership

- Environment

- Food & Wellness

- Sustainability / SDGs