Reading Time: 5minutes

Table of Contents

Combatting marine plastics in Indonesia

Plastic waste in the world’s oceans is a growing global concern. Marine plastics adversely impact the health of aquatic life; disrupt people’s livelihoods in fishing, tourism and other industries; compromise human food safety and quality; and disrupt coastal ecosystems by hindering plant growth and spreading invasive marine organisms and bacteria.

Worldwide, Indonesia is the second largest emitter of marine plastics, generating an estimated 6.8 million tons of plastic waste annually. Only 39% of that amount is collected, and much of it is landfilled without being sorted and recycled. The remaining 61% is simply burned or released into the environment, finding its way into the waterways and oceans of this, the world’s largest archipelago nation.

The government of Indonesia has set an ambitious goal of cutting marine plastics by 70% by 2025 by reducing plastic use and increasing collection. Under the principle of Extended Producer Responsibility (EPR), brand owners, manufacturers, importers and retailers must establish plans to limit and recycle their waste, adopt degradable packaging, and––starting in 2030––collect their own product packages for recycling. New regulations also call on consumers to reduce and manage home waste through reduction, recycling, and reuse.

Ajinomoto Indonesia realizes the need for plastic waste collection

Toshihiko Satake of PT Ajinomoto Indonesia’s Food Technology Division keenly felt the threat posed by marine plastics upon witnessing first-hand its effects on the local environment. “Large amounts of plastic debris had accumulated in a mangrove forest at the mouth of the estuary in Surabaya City, where I live,” he said. “The debris becomes entangled with the delicate mangrove saplings, damaging them and hindering their growth. Now, to preserve the mangrove forest that protects the estuary and its fragile ecosystem, saplings must be grown in a nursery and replanted once they’re big.”

Satake realized the Ajinomoto Group’s shift to more sustainable and recyclable packaging materials would not achieve its intended social value until those materials were collected. While collection systems for high-value trash such as plastic bottles and aluminum cans have steadily grown in Indonesia in recent years, collection of low-value multi-layered laminates, as used in food packaging, is only getting started. To make the Group’s efforts impactful, therefore, Satake decided the company needed to launch its own plastic collection initiative.

Sustainability Promotion Video 「Rekosistem Project」

Trial-and-error process leads to partnership with Rekosistem

Ajinomoto Indonesia began by trialing an initiative where employees brought their own packaging waste from home to the company for recycling. But the project was eventually wound down when it failed to show adequate growth potential as a waste collection model.

Realizing that building a system on their own was unrealistic, Satake and his colleagues sought out consortiums, NGOs, waste banks and waste management companies to collaborate with on new or existing projects. But due to the high cost of collecting multi-layered laminated packaging and the low prices paid by recyclers, they struggled to find sustainable initiatives. Three years’ efforts had yielded little progress when in 2022 the Japan International Cooperation Agency, hearing about Ajinomoto Indonesia’s efforts, invited Satake to speak at the Jakarta Japan Club.

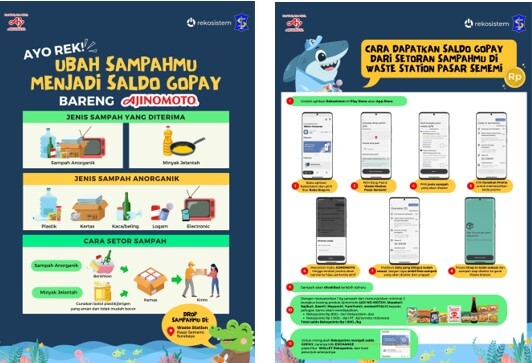

This helped set things in motion. A Japanese trading company representative present at the event later introduced Satake to Rekosistem, a local public-private partnership founded in 2018 to set up prefabricated collection stations in urban areas. Consumers bring their household plastic waste to the stations in exchange for digital credits they can convert into spendable currency using a mobile app. “By proactively communicating our thoughts on the environment and what we wanted to achieve, we became more visible to those around us,” says Satake, “and information and suggestions began to come in, which led to the eventual realization of our project.

With Ajinomoto Indonesia’s sponsorship, Rekosistem installed a plastic waste collection station in Pasar Sememi, a traditional marketplace in Surabaya City. The municipal government agreed to provide the land and electricity free of charge. Ajinomoto Indonesia also arranged to give users additional digital credits for bringing Ajinomoto packaging materials for collection along with their household plastic.

Toshihiko Satake of PTA Ajinomoto Indonesia’s Food Technology Division

Rekosistem’s prefabricated waste station, before artwork was added

Keys to success

Initially, says Satake, he and his colleagues were concerned about the project’s ability to win the approval of the city government. So they devised a waste collection system that benefits all stakeholders and therefore gained broad support. The city expects to reduce landfill waste through the program, and Ajinomoto Indonesia has undertaken to raise awareness and educate consumers about sorting waste and using Rekosistem’s mobile app.

Design of Waste station,The artwork features the famous Suramadu Bridge, as well as a shark and a crocodile, symbols of Surabaya City.

The project is a good example of how brand owners, including multinational companies, can work together to improve people’s lives in the countries where they operate. “Since this is a problem that concerns everyone,” comments Satake, “we have been able to win the cooperation of many, and the new connections we have made will have a positive impact on our existing business.”

With this initiative, Ajinomoto Indonesia has aimed to work with partners to contribute to social infrastructure which could be implemented throughout Indonesia,helping mitigate the problem of plastic pollution in rivers and oceans as “Health provider” that contributes to health for the earth.

As Sympathy Creation Team Lead, Mukti Mulyawan, Ajinomoto Indonesia’s Corporate Planning & Sustainability Section Manager, worked with Satake to build public support for the project by planning the station’s design, project incentives, educational materials, and the opening event

Educational materials designed by Mulyawan and the Sympathy Creation Team

The current waste station

Stories you may like

TOO GOOD TO WASTE™ initiative targets major source of food waste: our kitchens

- Environment

- Sustainability / SDGs

Sustainable skipjack: managing fisheries and reducing food loss

- Environment

- Sustainability / SDGs

Completing the bio-cycle: AJI-NO-MOTO® co-products help to boost agricultural output

- Environment

- Sustainability / SDGs