Reading Time: 4minutes

Table of Contents

If you like to cook from scratch, you must have noticed how much gets thrown away. Stems, seeds, leaves, peels—all go in the rubbish bin or down the disposal. The process of food production also generates such leftover materials. Some, like our kitchen waste, are discarded. Many, however, can be put to use as fertilizer or animal feed. These are called co-products.

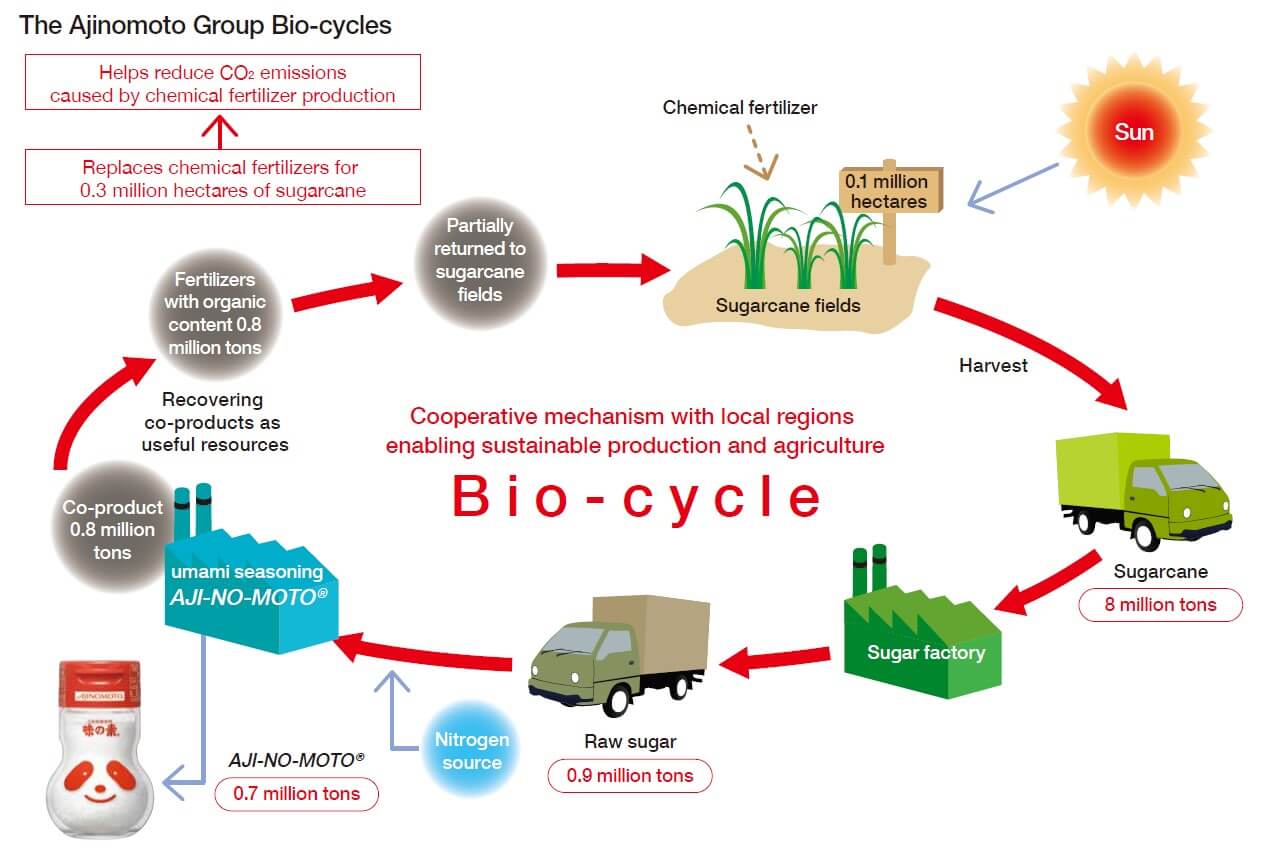

The Ajinomoto Group is working to turn waste from its AJI-NO-MOTO® manufacturing process into useful products like fertilizer. Through fermentation using microorganisms, the Group produces glutamate and other amino acids from crops such as sugarcane, cassava and corn. Annually, about 700,000 tons of the Group’s signature umami seasoning are produced this way, generating some 800,000 tons of leftover materials, 93% in the form of liquids from the fermentation process.

Harvesting cassava in Thailand

These fermentation liquids can be turned into useful co-products such as liquid fertilizer for sugarcane and other crops, and liquid animal feed. This circular process is called the bio-cycle. Currently, the Ajinomoto Group boasts a co-product conversion rate from amino acid fermentation production of nearly 100%.

The chart assumes worldwide annual Group production of approximately 0.7 million tons of the umami seasoning AJI-NO-MOTO® using only sugarcane. The figures for sugarcane grown and sugar production are commonly used global figures. The figures related to resources used for producing AJI-NO-MOTO® are based on actual statistics from the Group.

The key principle of the Group’s bio-cycle initiative was to convert nutrition-rich waste into useful fertilizer and other co-products, unleashing its value. As the environmental conservation movement began to grow worldwide in the 1980s, the Ajinomoto Group was taking action.

“In the 1980s the commercialization of co-products gave rise to the concept of the bio-cycle,” says Kazuhiko Kunita of Ajinomoto Co.’s Sustainability Promotion Department, who for years has been studying better ways to convert waste into co-products. “The idea to utilize liquid co-products such as fermentation liquid as fertilizer first arose at our subsidiary in the Philippines, where a joint venture called Union Hikari Fertilizer was set up to sell liquid fertilizer for sugarcane and other crops. The idea spread quickly to other countries like Indonesia, Thailand and Brazil.”.

Liquid co-products contain organic matter such as amino acids and other nutrients. Like compost and organic fertilizers, they nourish microorganisms in the soil and are beneficial to plant growth. And over 10 years of joint research with local universities and research institutes on the ground demonstrated no adverse effects on crops. “Now liquid co-products are sold as liquid fertilizer for crops and as liquid feed for livestock and aquaculture in Thailand, Vietnam, Brazil, and other countries where the Ajinomoto Group operates, contributing to improved agricultural output,” says Kunita.

FD Green (Thailand) harvesting cabbage grown with liquid fertilizer made of co-products

Worldwide, arable land is expected to decrease over the coming decades, even while the planet’s population continues to grow rapidly. The Ajinomoto Group is also investigating the feasibility of deriving amino acids from inedible leftover materials such as rice straw and sugarcane fibers, freeing up more edible crops like cassava for human consumption.

Avoiding future food crises will mean looking at our food from a different perspective and sometimes trying something new. If we want everyone to continue to eat well and live well, we must revolutionize the global food system.

The environmentalism of AJI-NO-MOTO®

Stories you may like

Sustainable skipjack: managing fisheries and reducing food loss

- Environment

- Food & Wellness

- Innovation

- Sustainability / SDGs

- Umami

Renewable biomass reduces CO₂ emissions

- Environment

- Food & Wellness

- Innovation

- Sustainability / SDGs

- Umami

AJI-NO-MOTO® paper packaging: reducing plastic waste

- Environment

- Food & Wellness

- Innovation

- Sustainability / SDGs

- Umami