Table of Contents

The Ajinomoto Group’s ASV Award honors initiatives that help solve society’s issues, leading to the creation of economic value through innovative and original business activities with our stakeholders and businesses.

The Gold Prize for FY 2022 was presented for the BRIDGE project, a groundbreaking value-chain-crossing project that contributed to the reduction of greenhouse gases through the global one-team. We heard about the project from its initiator, Kohei Ishikawa, General Manager of T-TEC (Thai Technology and Engineering Center) at Ajinomoto Co., (Thailand) Ltd. and President of FD GREEN (THAILAND) CO., LTD.

Passion for microbial research leads to joining the Ajinomoto Group

Kohei Ishikawa, wishing to dedicate his life to microbial research after encountering it at university, hoped to work at the Ajinomoto Group, which has world-leading amino acid fermentation technology. This desire was driven by an unusually strong passion for microbial research.

Ishikawa: I was greatly attracted to and saw limitless potential in microorganisms that are invisible to the eye yet create new substances, like how milk transforms into cheese or yogurt. The Ajinomoto Group has an assembly of talented researchers and offered a high-level research environment. I had a strong hope to continue my research in such an environment.

At the Research Institute for Bioscience Products & Fine Chemicals, Ishikawa engaged in research and development, simultaneously earning his doctorate. He found great fulfillment in seeing his research results become commercial products sent out to the world.

In 2012, Ishikawa was seconded to AJINOMOTO FOODS EUROPE S.A.S. and moved with his family to France, where he gained much stimulation and learning about his work and environmental issues.

Ishikawa: Whether in supermarkets or listening to my children talk about school, I could see that the public is taking environmental issues seriously, and seeing how certification labels had penetrated society, I keenly felt that sustainability is directly connected to corporate value. Interaction with people in departments closer to production, beyond those in labs, also changed my awareness. My desire grew stronger to advance sustainability initiatives through the business I am involved in.

Challenges faced by the MSG (monosodium glutamate)/umami business

Ishikawa says he was shocked at the state of sustainability in Japan after returning from his assignment in France. At the same time, he felt there were also issues in the environmental activities of the Ajinomoto Group’s umami business.

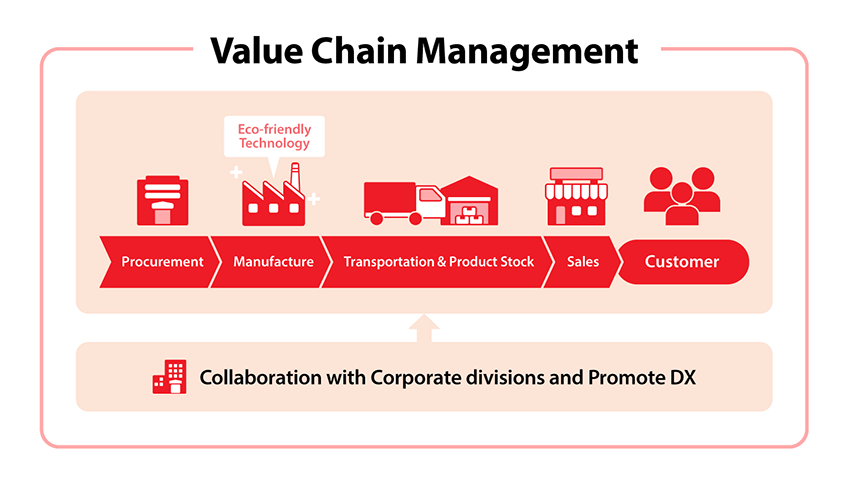

Ishikawa: Even as society as a whole is aiming for decarbonization and demanding the creation of eco-systems with low environmental impact, the umami business faced challenges such as its greenhouse gas emissions accounting for over 40% of total company-wide emissions. AJI-NO-MOTO®, the umami business’ representative product, is manufactured at 11 plants worldwide and sold in over 130 countries, with each region conducting wonderful initiatives addressing such issues. However, there was no system to share effective approaches and new technologies company-wide, so information did not reach groups facing similar challenges. Also, due to the leadership in my business division, collaboration between related departments was sometimes impeded, oftentimes delaying the introduction of new technologies developed in labs at production plants.

Thinking that changing the conventional vertically separated organizational structure was necessary to resolve these issues, Ishikawa conceived the idea for the cross-organizational BRIDGE project involving Group companies in and outside Japan.

Project Name:

BRIDGE (Building Umami R&D/production/business Integrated sustainable structure through DX and Group’s Environmentally friendly technology)

Launching and spreading BRIDGE

Ishikawa: Initially aiming to address environmental issues, we found that similar challenges existed across the value chain. Therefore, to strengthen the entire umami business, we decided to launch a cross-organizational project comprising the global value chain (R&D, production, industrial business sales, supply chain management). The five working teams constituting the project involved not just organizations in Japan but also overseas group companies in Thailand, Brazil, the United States, Indonesia, Vietnam, etc. It was a large project with over 100 people participating. We felt it was especially important to apply the ASV (Ajinomoto Group Creating Shared Value) philosophy to each aspect of our work. First, we set FY 2025 targets for social value (reducing CO2 emissions by 40%) and economic value (4 billion yen in business profit). Then, together with colleagues, we thoroughly considered concrete strategies and project management to achieve these objectives.

What is ASV (Ajinomoto Group Creating Shared Value)?

Specific measures included establishing a project structure transcending companies and organizations to share knowledge and information, systematizing sustained innovation creation, advancing development through the integration of labs and production, and creating a knowledge sharing structure between overseas group companies and plants.

Ishikawa: We believed just creating mechanisms would not make them function, so we focused on enhancing the motivation of personnel working towards our goals. To achieve this, an environment was needed where each work activity was felt to connect beyond one’s department and contribute an important piece to the overall value chain goal. Thus, we highlighted strengthening multifaceted communication beyond relying just on meetings. For example, each company posts status updates and information on the internal social media we set up, teaches best practices through online meetings, holds cross-organizational personal goal presentations, and more. This created an enjoyable, voluntary exchange environment where umami business members could interact and work with pride.

With members of the BRIDGE project.

People and information connect beyond company and departmental frameworks. The entire umami business works as one team towards a unified goal. As its name suggests, BRIDGE was about creating mechanisms to “bridge” the entire company and bring about a change of mindset. From the project’s conception, Ishikawa led the planning and proposal, with like-minded colleagues actively cooperating at launch. Eventually it gained much support and approval, spreading the passion embodied in the project across the company.

Outcomes of the BRIDGE project

The initiatives conducted through the project produced more than one result. Through those efforts, the project achieved cost reductions through efficiency improvements, greenhouse gas emission reductions through the use of environmentally friendly technologies, increased added value of products leveraging “low carbon” as a strength, inventories reductions through SCM improvements, as well as strong relationships of trust with customers through sustainability activities. It also led to maximizing synergy between teams and stronger employee engagement. We realized the “speed up × scale up” of strengthening and connecting the company’s intangible assets of human, technology, and organizations that we targeted at the project’s conception. This produced results in drastically reducing greenhouse gas emissions in MSG and nucleic acid manufacturing.

Ishikawa: The substantial contribution to the company-wide goal “to reduce environmental impact by 50% by 2030” in a short period of time was recognized, and BRIDGE’s efforts won the Gold Prize at the FY 2022 ASV Awards. I think the success and joy produced by the project also deepened understanding of ASV. Though we still have more to do, I’m proud of the results I achieved with wonderful colleagues, all with a smile.

At the ASV Awards ceremony

Further transformation of BRIDGE

Having gone through these phases, from 2023 we are reviewing and improving the project, and will continue making changes aiming for a business structure that can grow sustainably. Ishikawa says there is still room to evolve and create further value by encouraging people to take ASV as their own initiative, making it an ingrained part of our corporate culture, and by enhancing collaboration among Group companies.

Ishikawa: Although I stepped away from project management when I transferred to Ajinomoto Co., (Thailand) Ltd. in 2023, I’m now involved with BRIDGE from a more hands-on position. I think I can still contribute to the umami business, from a new perspective different from before.

With members in Thailand

Future outlook and vision

When asked for his outlook on the future, Ishikawa presented the clear goal of “establishing and evolving a bio-cycle.”

Ishikawa: I want to evolve the umami business’ circular economy by making high functional, high value-added organic fertilizers and agricultural materials from by-products of the MSG manufacturing process. In Thailand, I believe establishing sustainable agriculture that improves the productivity and income of cassava farmers while reducing environmental impact will lead to realizing ASV. BRIDGE is also part of this cycle, and I’m sure there is still room for further evolution.

“There is no limit to technological evolution, and people can always evolve too,” says Ishikawa. BRIDGE, which Ishikawa launched, nurtured, and brought to bloom, has taken root in the Ajinomoto Group and will spread limitlessly.

Stories you may like

Fueling Victory: The Ajinomoto Group’s Support for the SEA Games and ASEAN Para Games

- Food & Wellness

- Innovation

- Purpose

- Sustainability / SDGs

- Umami

【Flags】Diversity, equity, and inclusion in the Ajinomoto Group~Food Diversity Project

- Food & Wellness

- Innovation

- Purpose

- Sustainability / SDGs

- Umami

Advancing “AminoScience” for Climate and Agriculture: The Ajinomoto Group on Innovation and Impact

- Food & Wellness

- Innovation

- Purpose

- Sustainability / SDGs

- Umami